Recycled Parts Moderator Newsgroup, Discussion Board and Trading Place > Buy back Centers

> Metal

> Gold

> Vacuum forming machine thermo plastic sheet mold former

Vacuum forming machine thermo plastic sheet mold former

* Ready to use out of the box, table top design

* Heavy duty 10 ' grounded electrical cord

* Unit measures 26" high - 23" long - 12" wide

* Operates on household current 110 - 120 volt

* 220 - 240 volt is also available at no extra cost

* Maintenance free Galvanized seal less platen ( forming area )

* Plastic holding frame slides up and down quickly ( Teflon® coated ) before plastic starts to cool

* Incoloy® tubular long lasting heating element. Symmetrically engineered for uniform heat distribution to critical areas with no dead spots.

* Forming area 15 ¼ " by 10 ¼ " with small internal chamber to allow quick suction

* Depth of draw up to 7 inches depending on mold shape and plastic

* Plastic thickness up to 1/4 "

* Precut plastic (white, clear food safe, black and other colors) is available

* Only air between the mold and the platen is evacuated ( small internal chamber ) not the whole box without the need of spacers under the mold

* Portable unit with rubber feet (unit weighs 30 lbs.) Stainless steel, Aluminum, Galvanized steel is used to eliminate rust

* Unit comes with a built in hand pump (right side of the unit) for secondary high source vacuum ( pulls 27 In.Hg ).

* Additional outlets are integrated in to the unit which allows additional (storage tanks - vacuum pumps) to be connected to the unit if needed, opens automatically when suction is applied

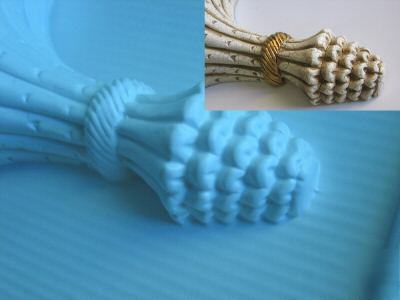

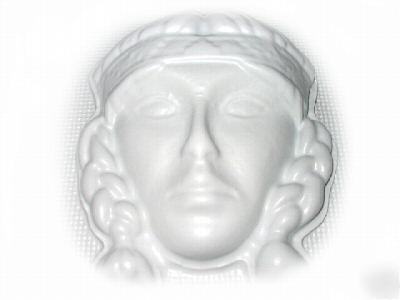

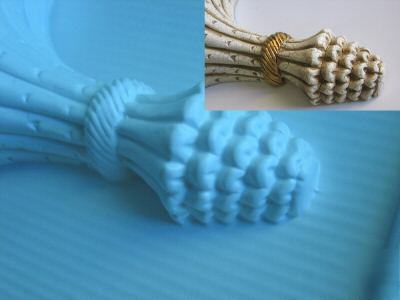

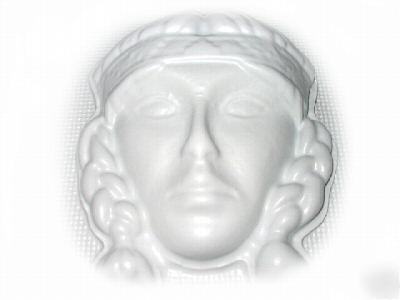

* 3 stage unit for extra forming power ( Excellent detail on formed parts)

* Unique handles on the sides allow the plastic frame to move up and down quickly and can be locked at any height.

* Operator’s Manual is included with pictures, sources for plastic and blister/skin packaging supplies, tricks on vacuum forming and molds

* The EZFORM SV 1510 works with all formable plastics which include : Styrene, Acrylic or Plexiglas, Pet-G, PVC, ABS, Polyethylene, vinyl, Lexan or polycarbonate, and many more

* This unit can be used for prototyping, Magnetic letters, molds for plaster/concrete/candy/chocolate, Packaging, Blister packaging, Skin Packaging, sign making, mask making, special effects, RC Parts (cowls - wingtips - canopies), slot car bodies and many more

* Transition from low to high vacuum is automatic with a small internal chamber which allows all the air to be removed quickly

* Limited lifetime warranty and free technical support

Place the plastic on the frame with the supplied clips. Place the mold(s) on the table. Turn the side clamps to loosen and bring the frame up to the oven, the plastic holding frame can be locked close or farther away from the oven. After the plastic gets soft turn on the vacuum and bring the frame down over the mold. The hot plastic will make contact with the galvanized platen and act as a seal (this design is maintenance free since there are no seals to wear out) The hot plastic will be sucked over the mold, at this point the pressure sensitive valve will temporarily close and you can use the included side hand pump ( pulls 27 In.Hg.) (or a secondary vacuum pump - storage tank of your choice) to create more vacuum if needed for more detail and thicker plastics. Let the plastic cool for about 5-10 seconds and you have a finished part (the cooled plastic retains the shape of the mold).

The EZFORM series are equipped with a high source handpump integrated into the unit, only the handle is visible. The machine has an elastic opening to attach your vacuum (shop vac or other common household vacuums) and also another additional outlet if you want to add an electric pump later on instead of the hand pump. This is how the machine works: The vacuum removes most of the air (it removes a lot of air fast but it does not have a lot of torque) a pressure sensitive valve closes automatically when the vacuum is no longer able to suction. What is left is evacuated by the handpump or you can add an electric pump later if needed (the pump or handpump removes less air but it has more torque) . By combining the 2 suction sources the transitions are automatic and and you can form thick plastics with great results . The versatility of the machine allows different suction combination to be used individually or a the same time.

* up and running in 5 min! great vac former for the price!

* I did my research and this is a great product and a great seller A+++

* Great machine, fits my operation just perfect! THANKS AAAAAAAAA+++++++++

* Quality product! Not a toy. WORKS PERFECTLY and EASY TO USE. FUN!! AAA+++

* Vacuum forming machine is simply amazing!! A terrific value for the money! WOW! A++

* Incredible machine. Fantastic support. If you are thinking about getting one of these, I highly recommend it!